A stationary Resource connected to some turret station or (Device put up) feeds the fabric in the rotating function bar and creates ideal styles.

The transmission structure of CNC vertical milling machines has been significantly simplified in the direct generate of the servo motor. However, to accomplish the processing of components with different styles, It is additionally essential for the machine Resource to efficiently and properly Handle a number of motors from the numerical Regulate system.

We also needs to on a regular basis Look at if the liquid filter screen is blocked, if the oil circuit is sleek, and when there is usual outflow of lubricating oil at Every single outlet.

While in the dynamic entire world of manufacturing, CNC machines have reworked how we create intricate patterns from Uncooked supplies. This web site delves to the fascinating realm of CNC machining, highlighting their pivotal part in contemporary industry. Understand the precision, automation, and flexibility which make CNC machines essential for high-excellent generation.

Additionally, it boosts uptime and is usually customizable to satisfy your part’s specs. Vertical machine centers have high speed and produce fantastic top quality.

Also, it is supplied with the automated PDI lubrication system to keep the machine operating effortlessly.

As you hunt down the ideal CNC mill in your smaller shop, you'll discover that not each CNC machine you come upon will show to get a great in shape for your personal work. The very best CNC machine is calibrated for your particular applications and capabilities.

Feed price refers to the velocity at which the cutting Software will work along the workpiece through its solitary Explore rotation.

A trustworthy title within the CNC machining earth, Fadal machines are constructed to previous. Like most vertical machining centers Within this price tag range, it has barely enough flexibility For each and every size machine shop.

The commonest troubleshooting technique is to replace a diagnosed defective circuit board by using a practical spare and carry out the necessary initialization and startup methods, permitting the machine Instrument to resume typical Procedure promptly. Then, the faulty circuit board is often fixed or changed.

The two machines possess different orientations that let you take pleasure in the depth that horizontal machining centers offer you or the precision that vertical machining brings to the desk.

Yet another advantage of vertical machining centers is that they're significantly extra rigid than horizontal machining centers. This is often on the grounds that vertical machining centers Possess a heavier base and even more robust construction.

Several vertical machining centers can conduct distinct machining functions, while others are suitable for particular specialised tasks. VMCs present several adjustment abilities and versatility and therefore are pretty resilient.

Most CNC vertical milling centers use recalculating coolant systems to make certain parts and cutter tools are very well lubricated. This coolant system generally makes use of water and soluble oil among a variety of liquids.

Andrea Barber Then & Now!

Andrea Barber Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now! Kelly Le Brock Then & Now!

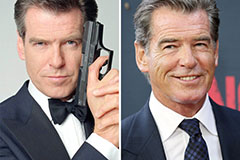

Kelly Le Brock Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!